Stay Ahead of Wear and Tear: Important Maintenance Tips for Undercarriage Parts

Stay Ahead of Wear and Tear: Important Maintenance Tips for Undercarriage Parts

Blog Article

Discover Undercarriage Parts for Heavy Machinery

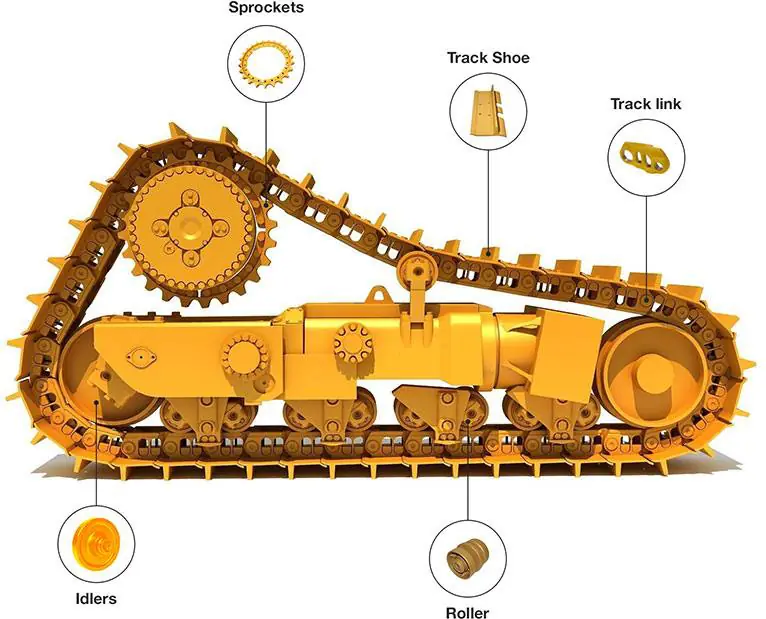

Comprehending the details of undercarriage components is necessary for the ideal efficiency and durability of heavy equipment. From track shoes to gears, idlers, and rollers, each element plays an important function in the functionality of the tools. Looking into the specifics of these components reveals a globe of accuracy engineering and toughness that keeps hefty machinery operating at its peak. Remain tuned as we uncover the relevance of undercarriage components and discover the maintenance practices that can boost the performance of these critical components.

Relevance of Undercarriage Parts

The undercarriage parts of hefty equipment play a critical duty in making sure the total efficiency and longevity of the equipment. These parts, including tracks, rollers, chains, gears, and idlers, develop the structure whereupon the equipment operates. A well-kept undercarriage not only supplies stability and assistance to the hefty machinery yet also contributes significantly to its functional efficiency and productivity.

One of the essential benefits of spending in premium undercarriage components is the decrease of downtime and maintenance expenses. By making use of long lasting parts that can stand up to the rigors of heavy-duty applications, operators can reduce the requirement for frequent repair work and substitutes, hence optimizing the maker's uptime and overall life expectancy.

In addition, appropriately working undercarriage parts guarantee optimum weight distribution, grip, and ability to move, enabling the hefty machinery to run smoothly also in tough terrains. This reliability is crucial for markets such as building, mining, and farming, where devices performance straight affects project timelines and earnings. To conclude, the value of undercarriage components can not be overstated in maintaining the effectiveness and longevity of hefty machinery.

Sorts Of Track Shoes

When considering the numerous sorts of track footwear for heavy equipment, it is important to assess their design and performance in relation to particular operational needs. Track shoes are critical components of the undercarriage system, supplying weight, stability, and grip circulation for hefty machinery such as excavators, bulldozers, and spider cranes.

The most typical kinds of track shoes include:

** Grouser Shoes **: Featuring raised steel bars (grousers) along the shoe's surface area, these track footwear give boosted grip in tough surfaces like mud, snow, and loosened gravel. undercarriage parts.

** Double Grouser Shoes **: Comparable to grouser shoes yet with an added set of grousers, these track shoes provide you can try this out even greater traction and security, making them perfect for incredibly rough terrains.

** Three-way Grouser Shoes **: With 3 sets of grousers, these track shoes provide optimal traction and stability, making them ideal for the most requiring problems.

Selecting the right sort of track shoe is crucial for optimizing the efficiency and durability of heavy equipment while making certain safety and security and performance during procedures.

Feature of Rollers and Idlers

Rollers and idlers play indispensable roles in supporting and assisting the track shoes of hefty machinery throughout procedure. By preventing excessive slack or rigidity in the tracks, idlers contribute to the overall security and efficiency of the machinery.

In addition, idlers and rollers interact to keep the track shoes abreast, avoiding them from slipping or hindering off during operation. Appropriately operating rollers try here and idlers are critical for guaranteeing the long life of the undercarriage system and making best use of the device's performance. Normal maintenance and evaluation of these parts are important to determine any kind of signs of wear or damages at an early stage, stopping pricey repair work and downtime in the future.

Duty of Gears in Equipment

Maintenance Tips for Undercarriage Parts

Reliable upkeep of undercarriage components is vital for making sure the long life and optimum performance of heavy machinery. Routine assessment of undercarriage components such as track chains, rollers, idlers, gears, and track shoes is important to stop costly repair services and unanticipated breakdowns. One key upkeep tip is to keep the undercarriage clean from debris, mud, and various other contaminants that can increase wear and corrosion. It is likewise essential to ensure proper track tension to stop premature wear on parts. Greasing the undercarriage components at recommended intervals aids to minimize friction and expand the life-span of the components. Keeping track of for any unusual noises, vibrations, or changes in machine performance can show possible problems with the undercarriage that require immediate interest. By following these upkeep ideas faithfully, hefty equipment operators can minimize downtime, lower operating costs, and maximize the efficiency of their equipment.

Conclusion

In verdict, the undercarriage parts of hefty equipment play a critical role in making certain the smooth functioning and longevity of the devices. Understanding the value of track shoes, idlers, sprockets, and rollers, look at these guys along with carrying out correct maintenance methods, can greatly affect the total performance and efficiency of the machinery (undercarriage parts). Normal evaluation and prompt substitute of damaged components are crucial in making best use of the life expectancy and efficiency of hefty equipment

Rollers and idlers play indispensable roles in sustaining and leading the track shoes of heavy machinery during operation.In heavy machinery, sprockets serve a critical feature in transferring power from the engine to the tracks, allowing the devices to move effectively and successfully. These components are linked to the axles or final drives of the equipment and work in combination with the tracks to move the equipment ahead or backward. Regular assessment of undercarriage components such as track chains, rollers, idlers, gears, and track shoes is critical to protect against costly repairs and unexpected failures. Understanding the importance of track footwear, idlers, gears, and rollers, as well as executing proper maintenance techniques, can greatly influence the total performance and effectiveness of the equipment.

Report this page